What is a Printed Circuit Board (PCB)? Structure, Function, and Applications Explained

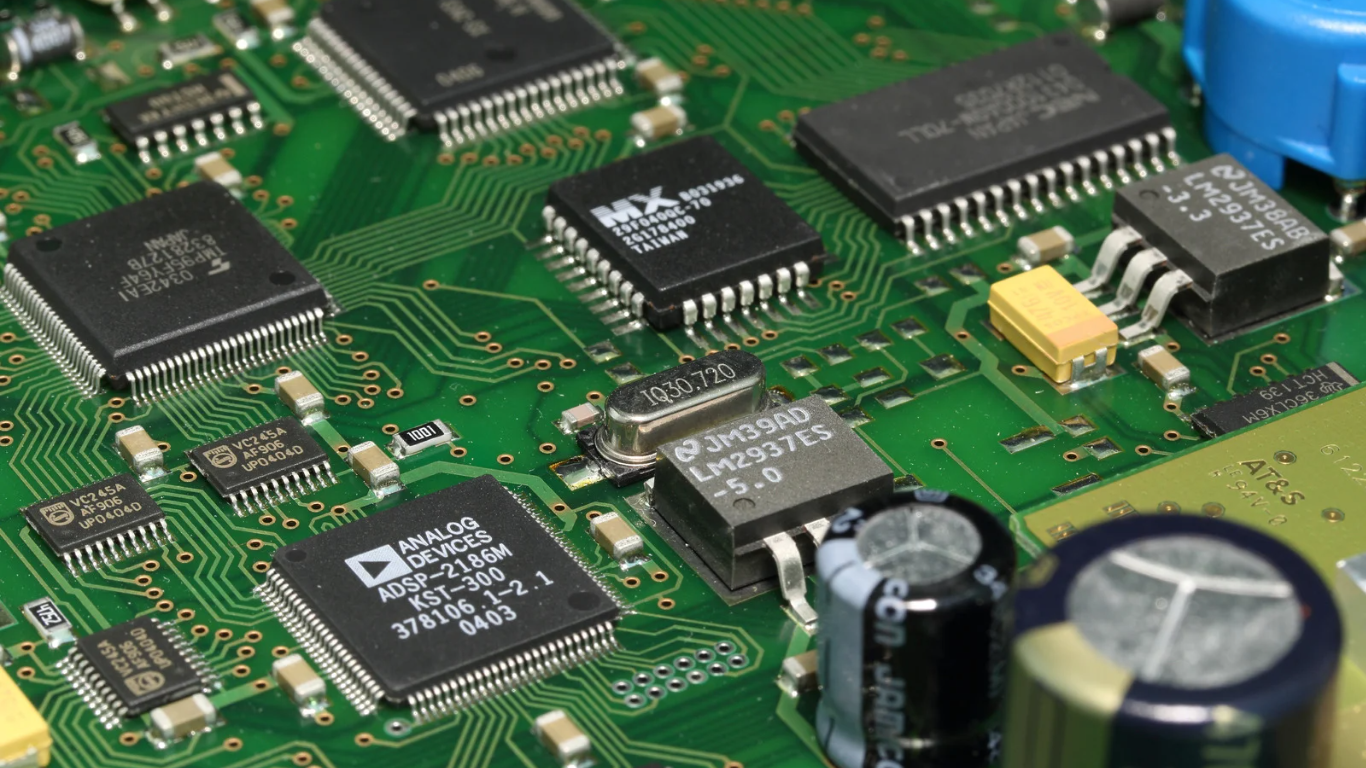

A PCB assembled with electronic components is called a printed circuit assembly (PCA), OR printed circuit board assembly (PCBA).

A PCB (printed circuit board) or PC board is a piece of phenolic or glass-epoxy board with copper clad on one or both sides. The portions of copper that are not needed are etched off, leaving “printed” circuits that connect the components.

PCB is used to mechanically support and electrically connect electronic components using conductive pathways, or traces, etched from copper sheets laminated onto a non-conductive substrate. It is also sometimes referred to as a printed wiring board (PWB) or etched wiring board.

What are printed circuit boards used for?

Using conductive paths, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate, a printed circuit board, or PCB, is used to mechanically support and electrically link electronic components.

Difference between a circuit board and a printed circuit board

A PCBA is a finished assembly that has all the components needed for the board to perform as needed for the desired application, as opposed to a PCB, which is a blank circuit board with no electrical components connected. A PCBA is prepared for usage in an electronic device when a PCB is not yet operational.

What material are PCBs made of?

Types of Printed Circuit Boards

Boards can be categorized into one of three categories: rigid, flex, or metal-core boards.

Rigid boards

Rigid boards, in which the pattern of the board is confined within a rigid substrate made from a high heat and pressure lamination technique, are frequently the vast majority of boards that a designer would meet. These boards are typically made of FR-4, although depending on the specific requirements of the design, this can be changed to highlight or otherwise enhance certain board properties.

Flexible boards

Metal-core PCBs

![]()