What is use of Dummy devices in Analog Layout?

The use of a dummy device is to provide the same environment as the matched device from all sides. Many processes require designers to insert dummies into the layout if they need matching devices for analog layout. Dummy devices help ensure that each device in a matching group has the same geometry when etched in silicon. Optical distortion resulting from sub-wavelength patterning is minimized by repeated patterns in the layout. By inserting dummies around the matching structures layout designers extend the pattern, meaning that the matched devices are inside the core of the etched pattern.

Dummy devices are inserted into the layout during certain processes to ensure that matching devices have consistent geometries when etched in silicon. They are particularly important for devices like current mirrors, where uniformity is crucial.

How does it help in Analog Layout?

These dummies help minimize optical distortion caused by sub-wavelength patterning by creating repeated patterns in the layout. While optical process correction techniques can address some issues, a uniformly patterned layout is preferred. By placing dummies around matching structures, layout designers extend the pattern, ensuring that matched devices remain within the core of the etched pattern and maintain uniformity.

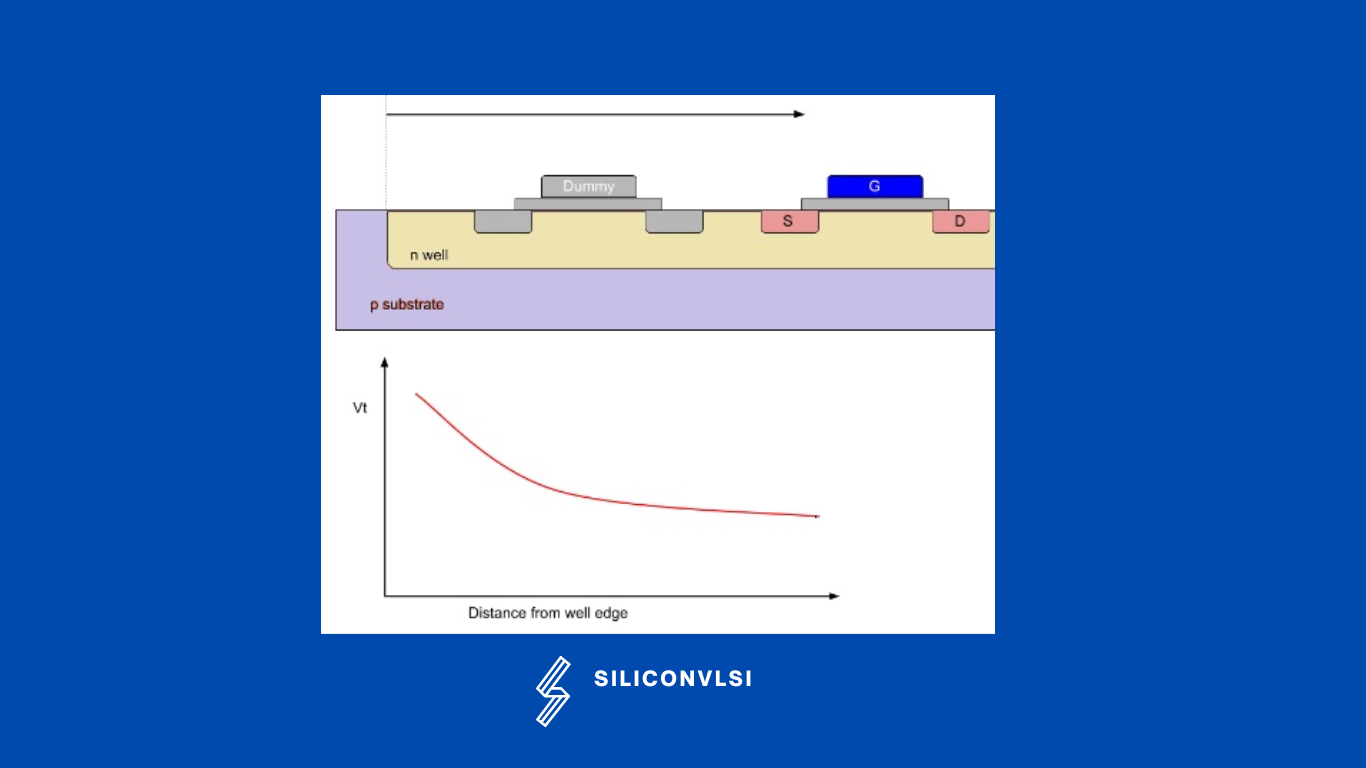

As you see above figure that near the Well edge, due to the scattering effect, doping concentrations are high so the vt of that is is more, so if we put a real device near the Well edge, then the Vt of that transistor will be different. so that’s why we are adding a dummy on either side to provide the same environment.