Skin Effect

When you work with conductors carrying alternating current (AC), you’ll notice a phenomenon called the skin effect. Unlike direct current (DC), which spreads evenly throughout the conductor, AC causes the current to concentrate near the surface. In this discussion, we’ll explore the factors that influence the skin effect and understand its impact on conductor resistance. By understanding these factors, we can make better design choices and reduce the negative effects of the skin effect on conductor performance.

Factors Affecting Skin Effect

Frequency plays a important role in the magnitude of skin effects. As the frequency increases, the skin effect becomes more pronounced. Conductors carrying radio frequency (RF) signals experience a significant skin effect, leading to a substantial increase in resistance. This phenomenon necessitates the implementation of remedial measures to mitigate its impact.

Conductor Shape The shape of the conductor also influences the skin effect. Solid conductors have a higher surface area compared to stranded conductors, resulting in a more pronounced skin effect. Consequently, stranded conductors are favored in applications where minimizing the skin effect is critical.

Conductor Diameter Skin effect is directly proportional to the diameter of the conductor. With larger diameters, the skin effect becomes more prominent. Therefore, when designing conductors, consideration should be given to minimizing diameter to mitigate the impact of skin effect.

Material Permeability Permeability, a material property associated with magnetic field formation, affects the skin effect. Materials with higher permeability exhibit a more significant skin effect. This correlation arises from the higher permeability material’s ability to generate a stronger magnetic field and subsequently increase self-inductance. The resulting higher reactive impedance forces current to flow primarily on the conductor’s surface.

Reasons for Skin Effect

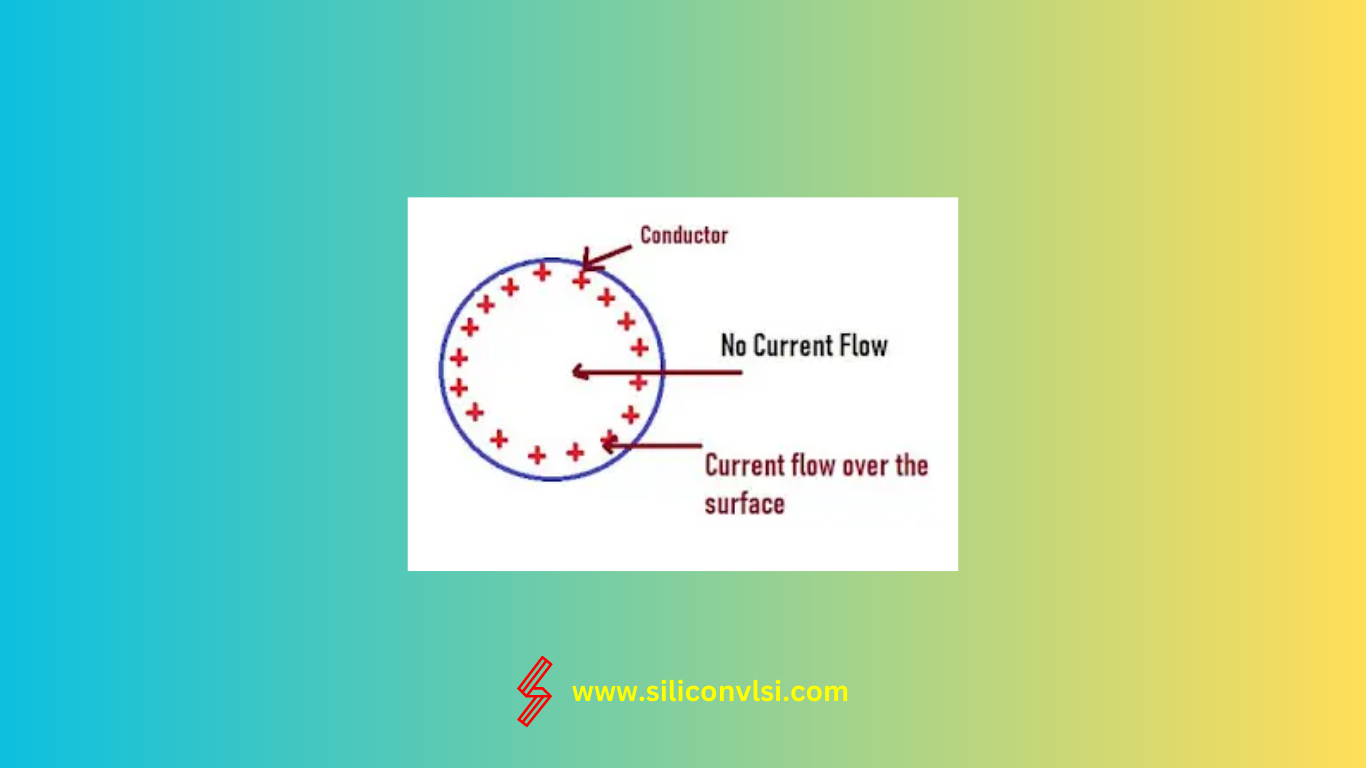

To understand the skin effect, we can consider a conductor composed of numerous cylindrical elements. When AC current flows through the conductor, a magnetic flux is established throughout its cross-sectional area. However, the flux linking to the cylindrical elements near the conductor’s surface is less than that linking to the elements near the core. As a result, the current concentration differs throughout the conductor’s cross-section, with higher concentrations near the surface and lower concentrations near the core.

The self-reactance of the inner and outer cylindrical elements further contributes to the non-uniform current distribution. The cylindrical elements near the core have higher reactance, leading to increased reactive impedance and reduced current flow. Consequently, the effective cross-sectional area of the conductor is reduced, causing an increase in resistance.

Conclusion Skin effect significantly impacts the performance of conductors carrying AC current. By considering the factors that influence skin effects, such as frequency, conductor shape, diameter, and material permeability, we can optimize conductor design and minimize resistance. Mitigating the adverse effects of skin effect is important for ensuring efficient and reliable electrical systems. Understanding the mechanisms behind the skin effect empowers engineers and designers to create more effective solutions for various applications.